Overview

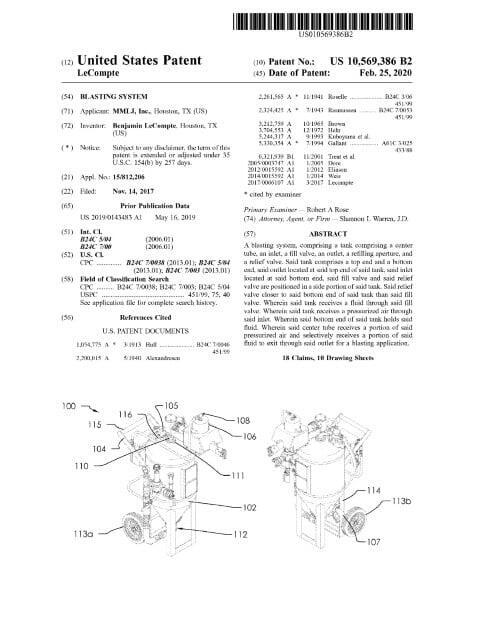

This patent details a robust blasting system that combines practical mechanical design with pneumatic control to improve slurry flow, pressure equalization, and operator safety. Filed on November 14, 2017 and granted on February 25, 2020, the disclosure — developed by inventors based in Houston, TX — captures several refinements that address common operational challenges in industrial blasting. The tank architecture features a center tube that selectively draws a pressurized air–fluid mixture, a novel venting cap that locks under lug nuts and requires depressurization to remove, and an integrated relief and fill-valve arrangement that precisely regulates fluid volume and pressure. A vibrator, strategically mounted on the shell and used with a conical interior angle and internal filter, keeps abrasive slurry mobilized to prevent clogging and enable reliable feed to the blast nozzle. The design also allows 360-degree hose rotation and a fail-safe pinch cutoff valve for added operator protection. The firm’s prosecution emphasizes clear functional claims and inventive mechanical interplay between hydraulic accumulators, the center tube coupling, and position-locking hardware, demonstrating deep technical drafting and claim strategy.

Key Features

- Selective center-tube air/fluid mixing with hydraulic accumulators

- Pressure-activated venting cap and relief valve control

- Vibrator-assisted slurry flow and anti-clogging geometry

- Fail-safe pinch cutoff and 360° blast-hose rotation

This patented system improves reliability and safety in abrasive-blasting operations and has broad relevance for industrial surface-preparation and fluid-handling equipment.

Granted: 2020-02-25