Overview

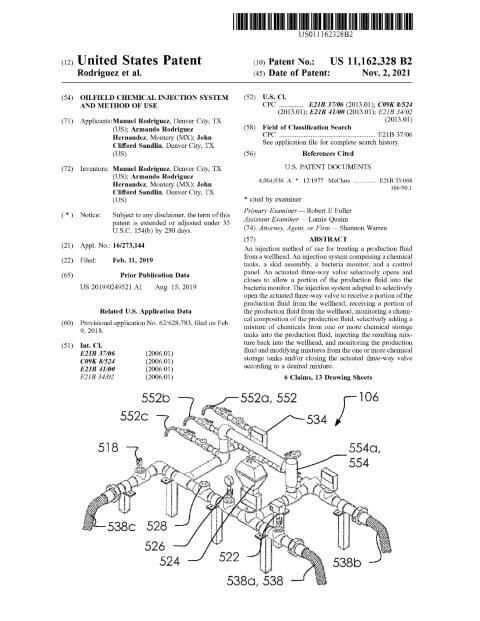

This patented oilfield injection solution delivers an integrated, skid-mounted system that automatically samples produced fluid, measures bacterial and chemical composition, and meters tailored chemical blends back into the well. Filed on February 11, 2019 and granted on November 2, 2021, the claimed technology combines multiple chemical storage tanks, dedicated electric pumps, flow meters, an explosion‑proof actuated three‑way valve, and a bacteria monitor under centralized control. Inventors based in Denver City, TX and Monterrey, MX designed the architecture to recycle production water, reduce truck dependence, and allow responsive on-site treatment driven by real‑time monitoring. The firm’s drafting highlights both practical field advantages and safety-conscious design choices that limit pressure-related hazards and environmental exposure. The prosecution emphasized metering, control logic, and mechanical segregation of tanks to mitigate overpressure and explosive risk — reflecting deep technical and claim-crafting expertise from our team.

Key Features

- Automated sampling and bacteria monitoring with control-panel feedback

- Multiple chemical tanks with individual electrically driven pumps for targeted treatments

- Electric flow meters for both chemical dose and production measurement

- Explosion‑proof actuated three‑way valve and relief switches for safety and pressure protection

- Skid-mounted layout for compact field deployment and truck‑replacement capability

By integrating responsive monitoring, precise metering, and explosion‑resistant control, the invention materially improves operational efficiency, water conservation, and safety for oilfield operators, with clear applicability across production and well intervention workflows.

Granted: 2021-11-02