Overview

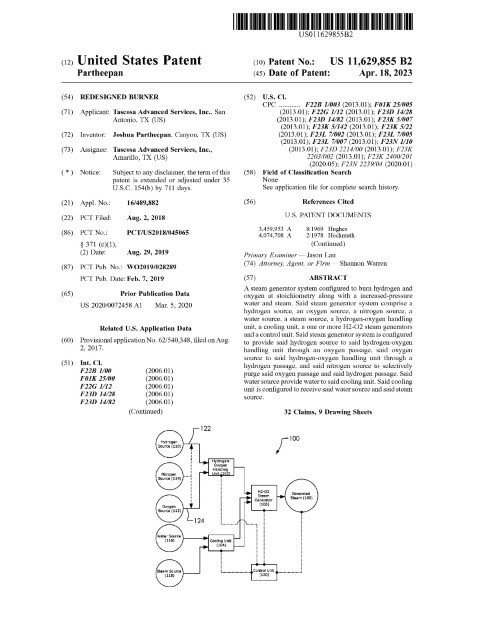

This patent describes a robust steam generator system that premixes hydrogen and oxygen at stoichiometry and pairs the combustion with controlled injection of high‑pressure water and cooling steam to produce high‑pressure, turbine‑ready steam. Filed in August 2018 and granted in April 2023, the disclosure (inventors based in Canyon, TX; applicant and assignee in San Antonio and Amarillo, TX) captures detailed safety, thermal‑management and control strategies that enable premixed H2‑O2 operation without flashback or thermal failure. Key drafting points include redundant flashback arrestors, mass‑flow control of reactants, a sintered‑plate quench and a burner‑tip geometry feeding a two‑pass steam generation chamber. Cooling is handled flexibly via a dedicated cooling unit that supplies high‑pressure water (≈2000 psi in embodiments), HP‑LT steam or a steam‑water mist; steam‑injector rings create a protective steam film on the liner to prevent thermal meltdown. The claims and specification also anticipate reusing a portion of generated steam for cooling and include a comprehensive control unit for closed‑loop monitoring and actuation.

This prosecution exemplifies the firm’s capability to translate complex combustion, materials and safety engineering into precise claim language that supports commercial deployment in power plants and mobile propulsion systems.

Key Features

- Stoichiometric premixed H2–O2 combustion with flashback mitigation

- Sintered plate and injector array for stabilized injection and quench

- Steam‑film liner cooling and two‑pass steam generation chamber

- Flexible coolant inputs: high‑pressure water, HP‑LT steam, or recycled steam

- Integrated control, sensing, and purge (N2) safety provisions

When supplied with renewable hydrogen, the system enables near‑zero combustion emissions for steam‑turbine and combined‑heat‑and‑power applications, positioning the technology for decarbonized industrial and transportation uses.

Granted: 2023-04-18