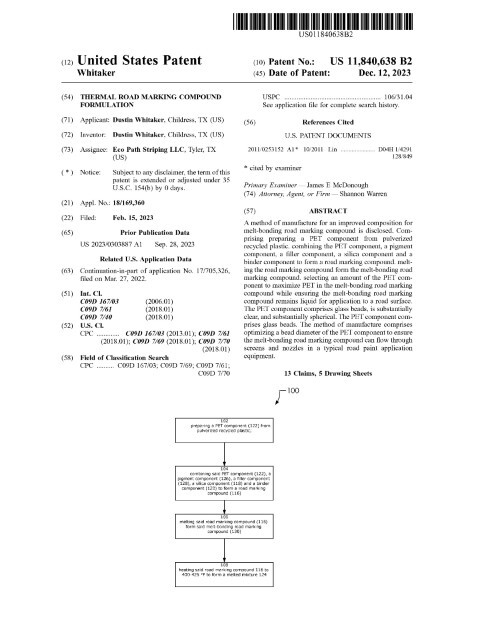

Overview

Our firm drafted and prosecuted claims that secure an inventive manufacturing approach for melt-bonding road marking compounds that incorporates pulverized recycled PET as a functional bead component. Filed on February 15, 2023 and granted on December 12, 2023, the patent covers practical formulation ranges and processing parameters that balance maximum recycled content with the flowability required for standard road-paint application equipment. Inventors based in Childress, Texas developed a clear, substantially spherical PET bead—sized and optimized (about 400–750 microns) to pass through screens and nozzles—so the compound can be melted and applied via conventional hot-melt kettles and spray or pump systems. The claims also specify composition ranges (by weight) such as 30–45% glass beads (silica), 20–42% calcium carbonate filler, 18–23% thermoplastic binder, and 1–20% PET, plus pigment options for white and yellow formulations. The method further contemplates heating to roughly 400–425° F to form an applicative melted mixture.

Our drafting emphasized both technical detail and enforceable scope: bead sizing, PET mass fractions, resin and filler tradeoffs, and processing temperatures are all claimed to enable durability improvements while increasing recycled-plastic content and lowering material cost.

Key Features

- Recycled PET beads optimized for flow (400–750 µm)

- Explicit component weight ranges enabling manufacturing control

- Processing temperature guidance (≈400–425°F)

- Environmental and wear-resistance benefits from increased PET

This patent aligns material science with practical road-maintenance workflows, advancing sustainable, cost-effective solutions for transportation infrastructure and recycled-material integration.

Granted: 2023-12-12