Overview

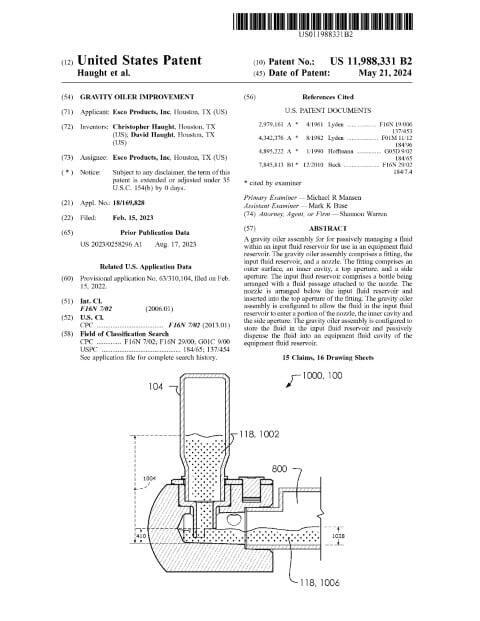

This patented assembly protects and passively manages lubricating fluid between a reversible input bottle and an equipment reservoir using a simple, robust mechanical interface. Filed February 15, 2023 and granted May 21, 2024, the claim set covers a fitting, an inverted input fluid reservoir that nests into a nozzle, and a nozzle/fitting geometry that meters oil into an equipment fluid cavity as levels fall. Inventors based in Houston, TX designed the device to rely on gravity and minimal moving parts—incorporating features such as a fluid notch to break surface tension, a threaded or O-ring seal to secure the bottle-to-nozzle interface, and an optional vent port to equalize pressure or support closed-loop recycling. The fitting may be transparent and includes a side aperture and inner cavity that interface with standard equipment fluid intakes. A dust shield and fastener protect the interface in industrial environments.

The result is a low-cost, maintenance-friendly lubricator that passively restores lubricant without pumps or electronics, reducing downtime and leak risk. Our firm’s drafting emphasized clear mechanical definitions and practical sealing/venting details to secure broad coverage for industrial lubrication applications.

Key Features

- Passive, gravity-driven fluid delivery with surface-tension break notch

- Integrated fitting with inner cavity and threaded side aperture

- Vent port for pressure equalization and closed-loop use

- Dust shield and sealing options (threading, O-ring)

This invention streamlines routine lubrication for heavy equipment and allied systems, offering a practical improvement with broad applicability across manufacturing and field service operations.

Granted: 2024-05-21