Overview

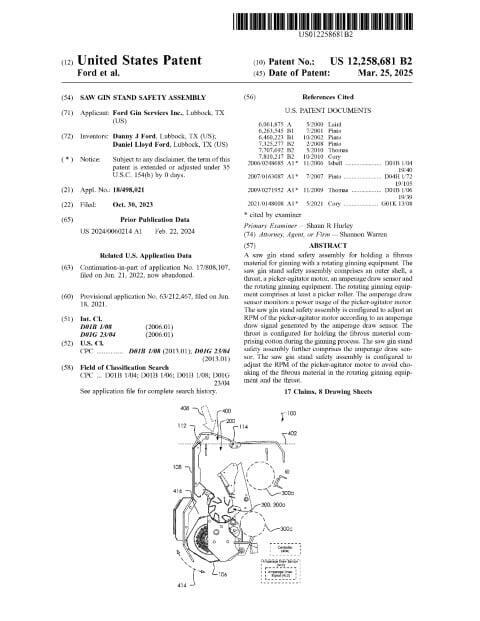

Filed October 30, 2023 and granted March 25, 2025, this patent describes a saw gin stand safety assembly that combines mechanical design improvements with sensor-driven control to increase capacity and reduce operational risk in cotton ginning. Inventors based in Lubbock, TX and an applicant based in Lubbock, TX developed an arrangement that isolates the picker-agitator motor on a variable-frequency drive and equips it with an amperage draw sensor. A dedicated controller interprets the amperage signal and dynamically adjusts picker-agitator RPM to prevent choking or clogs in the throat and rotating ginning equipment, while leaving the saw blade and brush assemblies to run at optimal speed. Hardware choices—direct drive relationships, in-cabinet motor mounting that removes idler belts, and an enlarged throat—combine with programmable control logic to deliver measurable improvements in throughput and safety. Additional design details, such as a lower front inspection window that functions as a fire-monitoring door, demonstrate attention to real-world operational hazards.

Key Features

- Sensor-driven RPM control using amperage draw to detect and respond to load

- Isolated picker-agitator drive (variable-frequency drive) to vary feed rate without slowing saw blade

- Enlarged throat and direct-drive layout for increased capacity and reduced belt complexity

- Lower front window serving as monitoring/fire door and improved service access

This patent exemplifies a practical convergence of mechanical refinement and embedded control to enhance safety and productivity in modern ginning operations, with clear relevance to agricultural machinery manufacturers and process-control integrators.

Granted: 2025-03-25