Overview

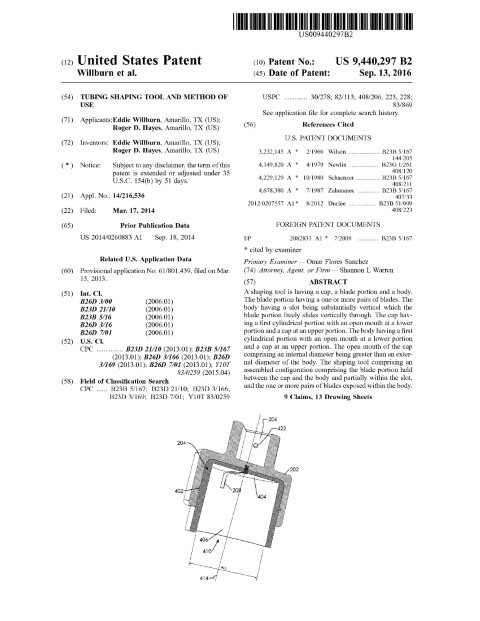

This patent describes a precision shaping tool engineered to trim and finish tubing ends using an assembled cap, blade portion, and cylindrical body. Filed on March 17, 2014 and granted on September 13, 2016, the disclosure—by inventors based in Amarillo, TX and assigned to applicants based in Amarillo, TX—details a vertical-slot blade carrier that slides into the body and exposes one or more pairs of blades within a cylindrical mouth sized to receive tubing. Thoughtful drafting captures practical features such as asymmetrical blade pairs (a sharpened cutter paired with a burnishing edge), a relief gap and venting apertures for debris control, knurled grips for secure manual handling, and an optional ratchet socket to apply torque. An alternative stepped configuration accommodates multiple external diameters, allowing a single tool to service different tubing sizes. The specification balances specific mechanical details with broad claims to protect variations in blade arrangement, stepped diameters, and assembly interlocks.

Key Features

- Vertical-slotted blade carrier with exposed cutting pairs

- Cutter + burnisher blade geometry for clean edges and deburring

- Stepped internal diameters to fit multiple tubing sizes

- Relief gap and vent apertures for debris management

- Optional ratchet socket and ergonomic grip

This well-drafted patent underlines the firm’s technical depth in mechanical tool design and pragmatic claim scope. The invention improves field efficiency and quality of tubing joins, with clear relevance to plumbing, HVAC, and manufacturing applications where reliable tube finishing matters.

Granted: 2016-09-13