Overview

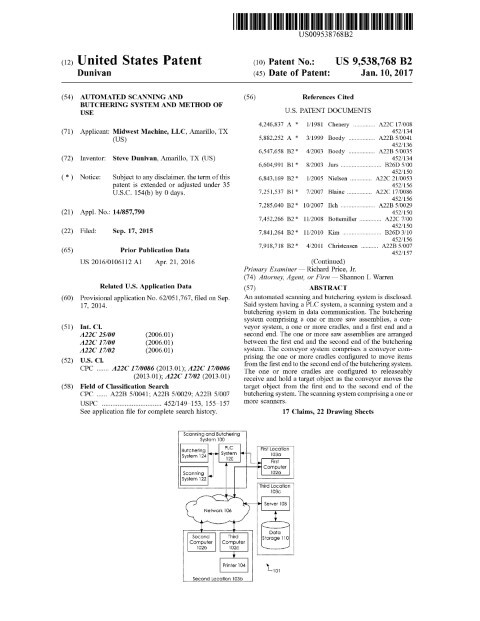

This patented system, filed in September 2015 and granted in January 2017, describes a fully integrated automated scanning and butchering line developed by inventors based in Amarillo, TX and assigned to Midwest Machine, LLC of Amarillo, TX. The disclosure captures system-level engineering that tightly couples a PLC with multi-head scanners, cradled conveyor transport, and one or more variable-height saw assemblies to produce consistent, data-driven cuts. The scanning subsystem constructs a 3D model of each carcass or cut, the PLC compares that model to stored templates, and the system calculates a trim line that drives servo-actuated saw positioning and conveyor sequencing. The resulting disclosure and claim set reflect careful draftsmanship in both apparatus and method claims, protecting integration points—drive assemblies with encoders, cradle fixtures, band-saw mechanics, and the PLC/scanner communication that optimizes yield and repeatability.

Key Features

- PLC-coordinated workflow linking 3D scanners to saw actuation and conveyor control

- Cradled conveyor with drive assembly, encoder, and configurable supports for different meats

- Band-saw assemblies with variable-height servo control for precise trim lines

- 3D model-to-standard comparison for automated trim-line calculation and reduced waste

- Networked data storage options for local or server-based processing

By automating scan-to-cut decisions, the invention improves throughput, yield consistency, and traceability in meat processing and offers a transferable approach for other automated material-cutting industries.

Granted: 2017-01-10