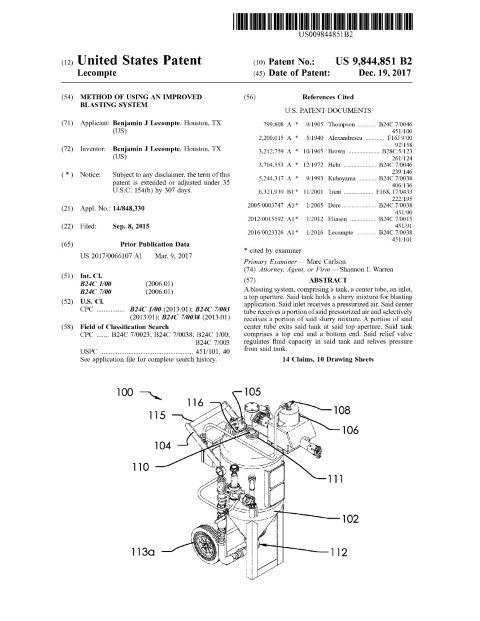

Overview

Our team obtained protection for a mechanically focused blasting system that improves slurry handling, pressure management, and operator safety. Filed on September 8, 2015 and granted on December 19, 2017, the patent—stemming from inventors based in Houston, TX and an applicant in Houston, TX—claims a tank-and-center-tube architecture that selectively draws slurry into a pressurized air stream, while integrated relief and fill valves regulate fluid capacity and pressure. The specification emphasizes practical refinements: a pressure-actuated venting cap, a sliding center tube that seals against a coupling nipple to create open and closed configurations, hydraulic accumulators that equalize pressure, and a vibrator plus an angled cone to keep abrasive slurry flowing without clogging. Detailed mechanical features such as a position-locking assembly, a fail-safe pinch cutoff valve with splash guard, and a rotatable center-tube/filter assembly underscore the drafting depth and claim scope achieved.

Key Features

- Center tube that selectively admits slurry and seals via a coupling nipple and position-locking assembly

- Pressure-retained venting cap and relief/fill valve arrangement for safe, controlled refilling and overflow management

- Vibration-assisted cone and filter geometry to prevent bridging or clogging of abrasive slurry

- Fail-safe pinch cutoff valve, splash guard, and hydraulic accumulators to equalize pressure and protect operators

By securing these claims, the patent strengthens product viability for industrial surface-preparation, pipeline maintenance, and corrosion-control equipment, highlighting both practical usability and improved safety in abrasive-blasting applications.

Granted: 2017-12-19