Overview

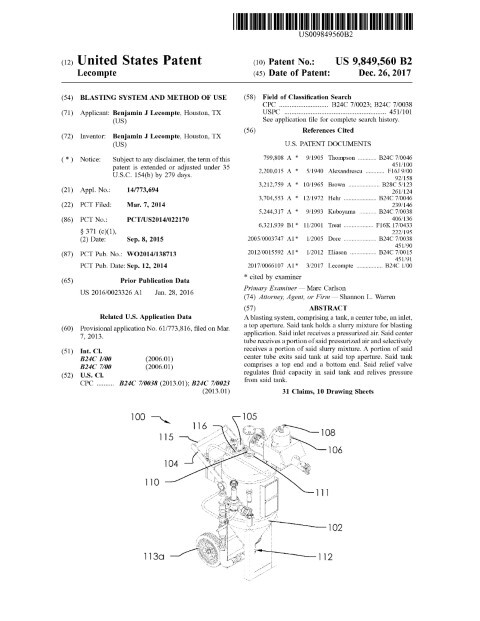

This patented blasting apparatus—filed in March 2014 and granted in December 2017—demonstrates precise engineering to manage the interaction between pressurized air and a slurry for controlled abrasive delivery. Inventors and applicants based in Houston, TX developed a tank-based system that uses a sliding center tube and a coupling nipple to switch between an air-only closed state and a mixed slurry/air open state. Integrated hydraulic accumulators equalize pressure between the center tube and tank to maintain steady fluid flow, while an internal filter, cone geometry, and an attached vibrator prevent clogging and preserve mixture consistency. Novel safety and usability features include a pressure-sealed venting cap that requires depressurization to remove, a failsafe pinch cutoff valve, a relief valve that regulates tank fluid capacity, and a splash guard for operator protection.

The firm’s drafting carefully captures the mechanical and fluid-dynamic interactions—claiming the coupling mechanism, pressure-equalizing accumulators, and user-safety assemblies—to provide broad yet precise protection for both component innovations and their synergistic operation.

Key Features

- Selective center-tube coupling (open/closed) for air/slurry control

- Hydraulic accumulators for pressure equalization

- Venting cap and relief valve for safe maintenance and overflow control

- Vibrator, filter, and cone geometry to prevent clogging

- Failsafe pinch valve and splash guard for operator safety

This disclosure advances industrial blasting by improving flow reliability, operator safety, and field serviceability—attributes important to industrial maintenance and surface-preparation markets.

Granted: 2017-12-26